Sectional fire gates EI 60

Completed works

Sectional fire gates MBA (FireTechnics) EI60 in stock

Sectional fire gates MBA (FireTechnics) EI60 in stock  Sectional fire-fighting gates for parking in Sechenova

Sectional fire-fighting gates for parking in Sechenova The principle of operation of lifting and sectional doors

The gate is closed by means of a 380 V electric drive (220 V is possible only with small gate sizes) in automatic mode. The final positions of the web are fixed by limit switches. The electric drive is controlled through the control unit, which is connected to the fire alarm system. When a fire alarm is received from the alarm panel, the barrier is lowered automatically.

In case of power outages, an emergency power supply can be installed. It is possible to install a gate for emergency evacuation and a hatch for a fire hydrant.

The main characteristics of fire-resistant gate sections

- At the request of the customer, it is possible to insert a gate with a fireproof lock and a fire-resistant hatch with a size of 200x200 mm;

- The highly reliable mechanism allows you to produce more than 25 thousand cycles of opening and closing the gate;

- Color version: any on the RAL scale (standard colors: RAL 7035; RAL 9010).

Canvas made of non-combustible panels

- It is made of movably connected sections of 0.5 mm thick sheet steel with a filler made of high-quality mineral wool;

- Profiles with a thickness of 2 mm are installed at the ends of the panels;

- Gate structure weight: 24 kg/m2;

- Web thickness: 60 mm;

- Panel height: 545 mm.

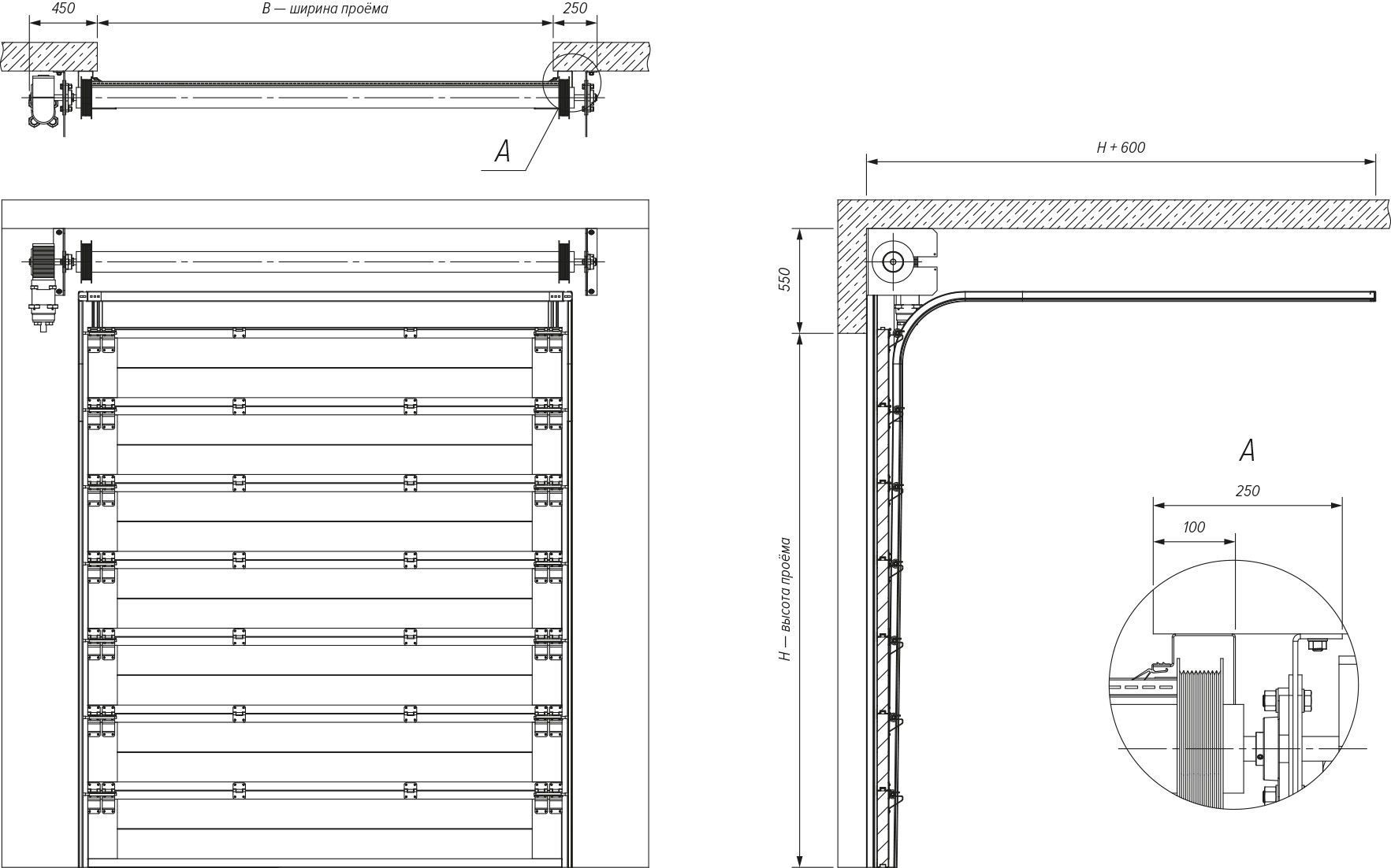

Installation options for sectional parking gates

Standard, High, Low, vertical.

Fire-fighting sectional doors with a standard lift look like ordinary industrial or garage sectional doors. But this is only at first glance, due to the use of non-combustible stone wool in the fabric of the gate, the mass of the structure is much larger and intensive use is prohibited. In addition, non-flammable lifting and sectional doors should work in conjunction with a fire alarm and descend automatically at a signal from the control panel.

Fire-resistant lifting gates with a vertical movement mechanism have their own additional advantages. Since the canvas, when lifting vertically, does not bend, that is, it is possible to make a structure without breaks - with a solid canvas. This allows you to avoid additional elements that may fail over time, as well as reduce the possibility of the occurrence of gorenje products in the places of articulation of panels.

Required space in the upper part of the opening for mounting the gate: at least 550 mm. The required place on the side of the electric drive installation: at least 450 mm. Required space on the side adjacent to the electric drive: at least 250 mm.

Dimensions

| Width, max | 7 000 mm |

| Height, max | 6 000 mm |

We manufacture products according to your individual sizes, there are no finished products. Contact your manager for help.

Advantages of fire gates MBA and FireTechnics

- The absence of springs, counterweights and other additional elements that often fail;

- The use of high-quality axial engines of European production;

- Integration with any emergency fire alarm systems;

- The possibility of manufacturing with an emergency evacuation gate and a hatch for a fire hydrant;

- Production according to European and world standards, quality certificate of the state sample;

- Low price, compared to European counterparts.

Features of operation of fire-resistant gates

The gate consists of a movable web that has the ability to move up and down, rigidly fixed load-bearing elements of the frame of the wall opening, as well as security devices, sealing elements. These elements are placed around the perimeter and are made of carbon material, which expands when heated and prevents the penetration of gorenje products.

As a standard, the gate is in an open state. The control unit (hereinafter referred to as the control unit) is connected to the security and fire alarm system (hereinafter referred to as the OPS) via a "dry contact". When a signal is received from the receiving and control device, the OPS BU sends a signal to the engine, the barrier closes the gap between the fire zones.It is forbidden to use fire-resistant gates as industrial ones (daily and multiple opening and closing during the day).- The maximum guaranteed resource is 5 cycles per day.

- Third parties and employees should not be allowed to operate the mechanism without familiarization with the technical passport.

- It is necessary to protect the structure from getting paint, putty, solvent, cement and other building materials on it.

- It is forbidden to attach building materials to the structure and clamp the guides between the finishing materials.

- Designed for operation in temperature conditions from -10°C to +40 °C.

- They are not intended for use in rooms with high humidity.

- You can not place any objects in the area of the gate and block them in any other way.

- If a regular technical inspection has not been carried out, then it is necessary to start the gate in the presence of a representative of the manufacturer or an authorized company.

- It is forbidden to change the power supply phases on the control panel after they are connected.

- It is forbidden to leave foreign objects, garbage and other materials in the area of the gate.

- It is not allowed to exert any mechanical influence on the gate (to lean stepladders, scaffolding, bags and any other objects).

- Any interference with the design and automation is prohibited.

- It is impossible to accelerate the movement of the canvas when they close themselves.